To optimize and automate internal logistics processes, ROBOPAC chose Connect Orchestrator AI

Digitalization and streamlining of logistics processes, reduction of errors and operating costs, operator–AGV integration.

CHALLENGE

There are still many manufacturing companies where the material picking process for the production line, the so-called “supermarket,” is tied to old patterns that persist over time.

Robopac’s goal was to digitalize the process with a solution interfaced in real time with the WMS in use, capable of coordinating different OT technologies, with the aim of eliminating paper and label printing, enabling hands-free manual operations, automatically identifying carts, and moving them with AGVs toward production.

SOLUTION

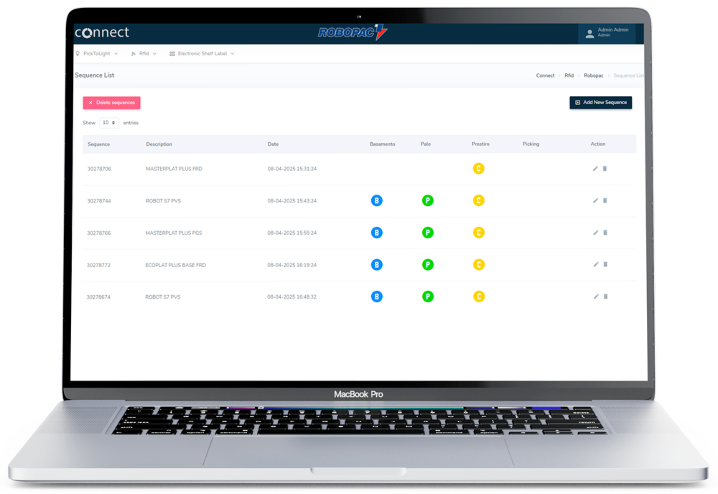

FasThink’s Connect Orchestrator AI software is the platform for integrating OT technologies with factory management systems (WMS/MES/ERP).

Connect Orchestrator AI, installed on the customer’s virtual servers, was interfaced with the WMS in use via API/web services.

Robopac chose FasThink’s wireless & touchless Pick2Light system for high-frequency component picking (>10 times a day) and opted for the wireless ESL Electronic Shelf Label system for those with low picking frequency.

Each cart was equipped with a passive UHF RFID tag and an ESL in place of traditional adhesive labels; RFID antennas installed along the route at key points allow automatic identification of the cart, which is previously associated with a production order.

The operator starts the process simply by communicating the assignment of the production order through the Android APP installed on a portable device.

RESULT

Thanks to Connect Orchestrator AI, material picking and cart handling in production and logistics lines have been automated and digitalized.

Operators carry out the picking activity in an intuitive and simple way, following the Pick2Light LED lights or the ESL displays without the need to print paper lists or use barcode scanners.

The interface with the WMS allows real-time management of production orders and related logistics activities.

Every activity is monitored and orchestrated by Connect Orchestrator AI, which collects and makes available useful data to management, who can measure performance, process lead times, identify potential inefficiencies, and implement changes and improvements.

Reduction of printing costs for paper lists or adhesive labels

Reduction of errors

Improvement of process visibility and coordination

Increase in operational effectiveness and real-time monitoring

Monitoring and analysis of performance (KPI)

Optimization of resources and operating costs

Automation and Digitalization of the logistics flow and cart handling

Greater flexibility

Sustainability

Discover Connect Orchestrator

USE CASE